Transforming Manufacturing: The Rise of Autonomous Robots and Next-Gen Automation

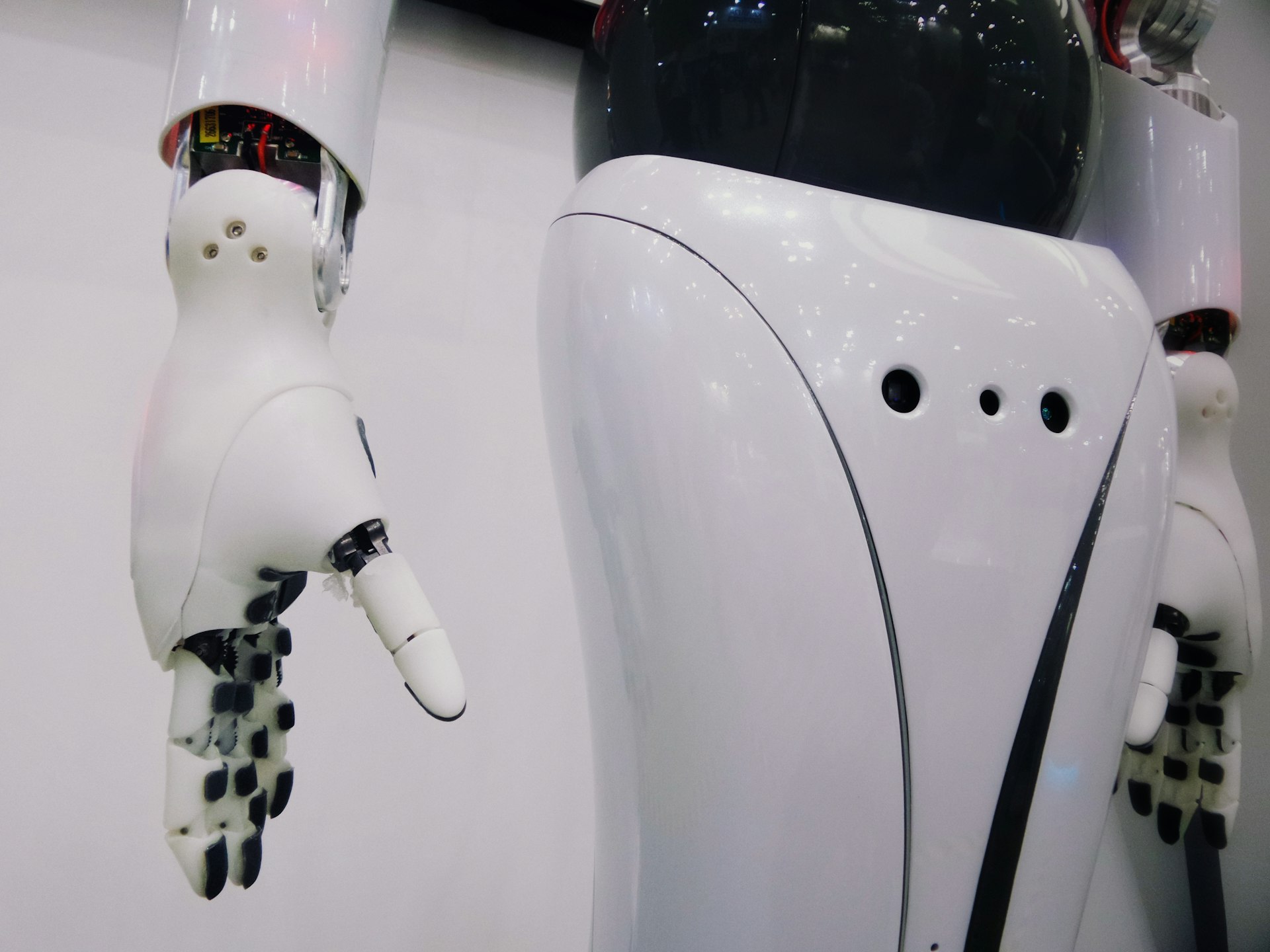

Photo by Possessed Photography on Unsplash

Introduction: Manufacturing’s Autonomous Revolution

The manufacturing industry is undergoing a profound transformation driven by the rise of autonomous robots. These machines, powered by advanced artificial intelligence (AI), machine learning, and sensor technologies, are reshaping how products are designed, assembled, and delivered. The integration of autonomous robots goes beyond mere automation-it is about creating smart, adaptive systems that work alongside humans, boost efficiency, enhance safety, and support sustainability objectives [1] . This article explores the key trends, benefits, real-world applications, and actionable guidance for manufacturers considering or expanding their use of autonomous robotics.

Key Trends Driving Autonomous Robotics in Manufacturing

Several critical trends are shaping the adoption and evolution of autonomous robots in the manufacturing sector:

1. Advanced AI and Machine Learning Integration

Modern autonomous robots leverage AI to process complex data, adapt to changing environments, and optimize workflows without human intervention. This evolution allows robots to handle diverse tasks, from precision assembly to intricate quality control. Generative AI-driven interfaces make programming more intuitive-users can now guide robots using natural language, reducing the need for specialized coding skills [1] . Such adaptability enhances productivity and allows for rapid reconfiguration of production lines in response to market demands.

2. Collaborative Robots (Cobots) and Human-Robot Teamwork

Collaborative robots, or cobots, are designed to operate safely alongside human workers. Enhanced safety features, such as obstacle and human detection, mean that cobots can dynamically adjust their actions to prevent accidents. These robots complement human skills, taking on repetitive or hazardous tasks while humans focus on complex or creative work. Cobots are increasingly user-friendly, with interfaces that reduce training time and empower workers to interact and collaborate with robotic systems efficiently [1] .

3. Autonomous Mobile Robots (AMRs) and Flexible Logistics

AMRs navigate dynamic environments, transporting materials and components throughout factories without fixed infrastructure. Their advanced sensor suites allow them to avoid obstacles and adapt routes in real time, minimizing delays and enhancing safety. AMRs are especially valuable for just-in-time manufacturing, where flexible material movement is critical. This capability helps manufacturers reduce inventory costs and respond swiftly to production changes [2] .

4. Digital Twins and Virtual Commissioning

Digital twins-virtual replicas of physical systems-enable manufacturers to simulate and optimize robotic workflows before physical deployment. Over a third of organizations already use digital twins extensively, accelerating deployment, reducing downtime, and minimizing costly errors [3] . Virtual commissioning allows teams to test and refine robotic processes in a risk-free digital environment, ensuring smooth real-world implementation.

5. Sustainability and Efficiency

Autonomous robots drive sustainability by reducing material waste, optimizing energy consumption, and enabling the efficient production of green technologies such as batteries and solar panels. Recent innovations include lightweight robotic components and energy-saving modes, which further decrease operational costs and environmental impact [5] . These advances support compliance with global sustainability goals and regulatory requirements.

Benefits of Autonomous Robots in Manufacturing

The adoption of autonomous robots delivers measurable benefits:

- Increased Productivity: Robots work continuously without fatigue, enabling higher throughput and faster cycle times.

- Enhanced Safety: By handling hazardous or repetitive tasks, robots minimize workplace injuries and improve overall safety standards [2] .

- Consistent Quality: Robots perform tasks with high precision, reducing defects and ensuring consistent product quality [5] .

- Cost Savings: While initial investment can be significant, long-term savings from improved efficiency and reduced waste often outweigh upfront costs. Innovations like Robot-as-a-Service (RaaS) models allow businesses to access cutting-edge robotics without heavy capital expenditures [5] .

- Flexibility: Modern robots can be easily reprogrammed for new tasks, supporting agile manufacturing and rapid product changes.

Implementation: How Manufacturers Can Adopt Autonomous Robots

For manufacturers considering automation, the following step-by-step guidance outlines how to successfully implement autonomous robotics:

Step 1: Assess Operational Needs

Begin by evaluating your production processes to identify repetitive, hazardous, or high-precision tasks where robotics can deliver the most value. Engage with line managers and operators for insights on current bottlenecks and pain points.

Step 2: Research Solutions and Vendors

Investigate leading robotics companies with proven expertise in your industry. Some of the top global players include ABB Ltd., Fanuc Corporation, and KUKA AG, all of which have extensive track records in automating manufacturing and assembly lines [4] . Review case studies and request demonstrations to understand how their solutions could fit your operations.

Photo by Alber on Unsplash

Step 3: Pilot and Scale

Start with a pilot project in a specific production area. Use digital twins to simulate integration and address potential issues before deployment. Gradually scale up, using data and feedback to refine processes and expand automation across your facility [3] .

Step 4: Workforce Training and Change Management

Invest in workforce training to ensure employees can safely interact with and leverage robotic systems. Many vendors offer tailored training programs. Transparent communication about the role of automation and upskilling opportunities can help alleviate worker concerns and foster a culture of innovation.

Step 5: Explore Financing and RaaS Models

For businesses concerned about high upfront costs, consider Robot-as-a-Service providers who offer robotics solutions on a subscription or usage basis. This approach reduces capital risk and allows for more flexible adoption as business needs evolve [5] .

Examples and Case Studies

Many manufacturers worldwide are already realizing the benefits of autonomous robots:

- Automotive Assembly: KUKA AG’s robots streamline car assembly, reduce human error, and improve consistency [4] .

- Electronics Manufacturing: Fanuc’s robots power high-precision electronics production, increasing throughput and minimizing defects.

- Green Technology: Autonomous systems manufacture critical components for solar panels and batteries at scale, supporting sustainable energy rollouts [5] .

- Small and Medium Enterprises (SMEs): Low-cost robotics and RaaS models are enabling SMEs to automate for the first time, overcoming traditional barriers to entry.

Common Challenges and Solutions

Despite the benefits, manufacturers should be aware of several challenges:

- High Initial Investment: The cost of cutting-edge robotics remains a major barrier. RaaS and low-cost robotics offer alternatives for gradual adoption [5] .

- Integration Complexity: Incorporating autonomous robots into legacy systems can be complex. Digital twins and simulation tools can help identify integration issues early [3] .

- Workforce Adaptation: Upskilling employees and clear communication are essential for successful transition and to realize full value from automation.

- Cybersecurity Risks: As robots become more connected, manufacturers must invest in robust cybersecurity protocols to safeguard both data and operations.

Alternative Approaches and Future Outlook

Manufacturers unable to invest in full autonomy can benefit from semi-autonomous or collaborative robots, which require less infrastructure and can be deployed incrementally. Some may prioritize task-specific automation, such as pick-and-place or inspection robots, before expanding to broader workflows. The industry consensus is that high-level adaptive autonomy will become increasingly feasible within the next five years, accelerating deployment and innovation [3] .

How to Access Robotics Solutions and Next Steps

To explore autonomous robotics for your manufacturing operation:

- Research top robotics providers like ABB, Fanuc, and KUKA for case studies and solution portfolios.

- Contact your local or regional manufacturing technology association for unbiased guidance and referrals.

- Attend industry trade shows and robotics expos to see demonstrations and connect with vendors directly.

- Consult with automation integrators who can assess facility needs and design a phased implementation plan.

- For financing, ask vendors about RaaS and leasing options, or consult with your business bank about equipment loans.

If you are unsure where to start, consider searching for “manufacturing robotics consulting” and “robotic system integrators” in your region. Many organizations offer free initial assessments or webinars to help businesses understand their options.

References

- Computar (2025). 2025 Trends in Robotics: Key advances in AI and collaborative robots.

- Novus Hi-Tech (2025). Manufacturing Industrial Robots: Trends in AI and AMRs.

- Studio Red (2025). Robotics Trends Transforming Industries in 2025.

- ETF Trends (2025). Top Robotics Companies Transforming the Industry in 2025.

- International Federation of Robotics (2025). Top 5 Global Robotics Trends.