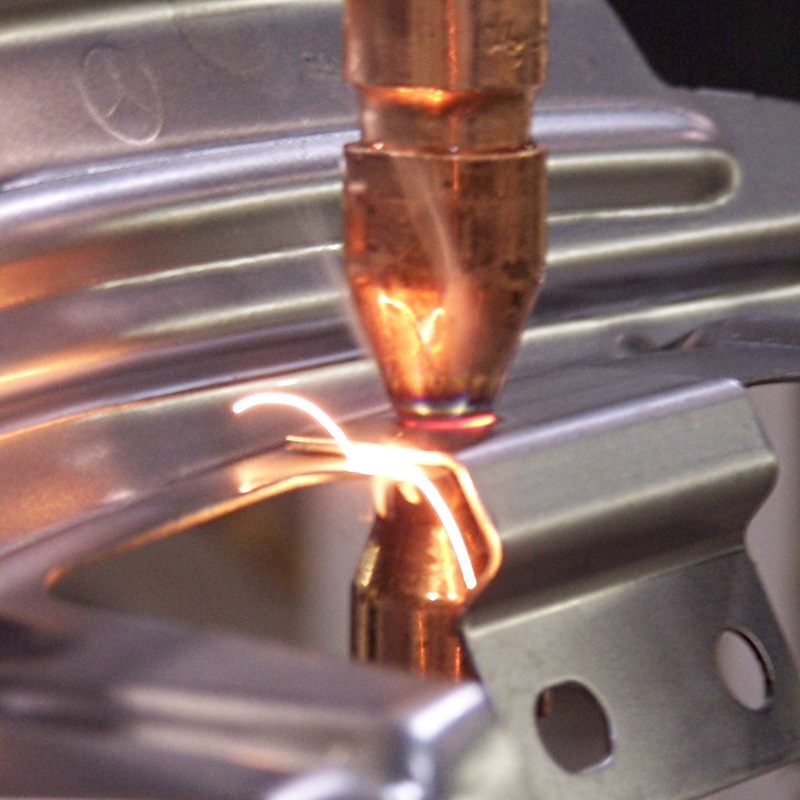

Welding Equipment in Automotive Shops: Essential Tools for Vehicle Repair and Restoration

Understanding welding equipment in automotive repair

Welding play a crucial role in automotive repair and restoration. From fix damage frames to fabricate custom parts, the right welding equipment make all the difference in the quality and durability of repairs. Automotive shops utilize various specialized welding tools design to handle the unique challenges of vehicle metalwork.

Unlike general welding applications, automotive welding oftentimes require work with thin gauge metals, specialized alloys, and in tight spaces. This demand equipment that offer precision, versatility, and appropriate power settings to prevent warping or burn through materials.

Source: theweldingmaster.com

MIG welders: the automotive shop workhorse

Metal inert gas (mMIG)welders stand as the nigh common welding equipment find in automotive repair facilities. These welders use a anncessantly feed wire electrode and a shielding gas to create strong, clean welds that are ideal for automotive applications.

The popularity of MIG welders in automotive shops stem from several key advantages:

-

Versatility

Capable of weld various metals include mild steel, stainless steel, and aluminum -

Speed

Allows for faster welding compare to other methods, improve shop efficiency -

Clean welds

Produce minimal spatter and slag, reduce post weld cleanup time -

Ease of use

Require less training to achieve acceptable results compare to TIG welding -

Adjustable settings

Modern units offer precise control over wire feed speed and voltage

Professional automotive shops typically invest in 220 volt MIG welders with output ranges between 30 200 amps. This power range provides the flexibility to work on everything from thin body panels to thicker frame components. Many modernMIGg welders too feature dual voltage capabilities( 110v/220v), allow shops to adapt to different power supply situations.

MIG welder accessories for automotive applications

Beyond the base unit, automotive MIG welding setups include several specialized components:

-

Wire feed systems

Quality drive rollers ensure consistent wire feeding for smooth welds -

Multiple gun tips

Different sizes accommodate various material thicknesses -

Gas regulators

Precise control of shielding gas flow for optimal weld protection -

Spool guns

Specialized attachments for aluminum welding that prevent wire feeding issues

Many automotive shops opt for MIG welders with pulse capabilities, which deliver control bursts of power. This feature help when weld thin auto body panels, reduce the risk of burn through while maintain adequate penetration.

TIG welders: precision for specialty work

Tungsten inert gas (tTIG)welders represent the pinnacle of precision in automotive welding. While require more skill to master, tiTIGelding deliver unmatched results for certain automotive applications.

Automotive shops utilize TIG welders mainly for:

-

Aluminum components

Especially for custom fabrication or repair aluminum body panels -

Thin gauge metals

When work with delicate sheet metal that could well burn through -

Stainless steel exhaust systems

Create clean, durable connections in performance exhaust fabrication -

Restoration projects

When appearance matter equally often as structural integrity -

Custom fabrication

Create one off parts that require superior finish quality

Professional automotive TIG welders typically feature ac / DC functionality, allow them to work with both aluminum (ac )and steel ( ( DC)dvanced models include foot pedals for amperage control, which give welders precise heat management during the welding process — critical when work on thin automotive metals.

TIG welder components for automotive applications

A complete TIG setup in an automotive shop include:

-

Various tungsten electrode size

Typically range from 1/16″ to 3/32 ” or automotive work -

Assorted ceramic cups

Different diameters to control gas coverage area -

Filler rods

Various alloys select to match the base metals being welded -

Gas lenses

For improved gas coverage in tight or awkward positions -

Flexible gas hoses

Allow access too difficult to reach areas in vehicle structures

High-end automotive shops oft invest in TIG welders with programmable memory settings. These allow technicians to save optimal parameters for different materials and thicknesses, ensure consistency across multiple repair jobs.

Spot welders: essential for body panel work

Spot welders serve a specific but critical function in automotive repair shops. These specialized machines recreate factory spot welds when replace body panels, ensure structural integrity equivalent to original manufacturer specifications.

Modern automotive spot welders feature:

-

Microprocessor control

Mechanically adjust current and weld time base on material thickness -

Water cool systems

Prevent overheating during consecutive spot welds -

Multiple welding arms

Different configurations to access various areas of the vehicle -

Pressure monitoring

Ensures consistent clamp force for reliable weld quality -

Weld quality testing

Some advanced units can test spot weld strength

Professional body shops typically use single phase 220v spot welders with output capabilities range from 8,000 13,000 amps. This power range allows them to efficaciously join the high strength steels progressively common in modern vehicle construction.

Spot welder adaptability for modern vehicles

As vehicle construction evolve, hence besides must spot welding equipment. Today’s automotive spot welders come with specialized programs for:

-

High strength steel (hHSS)

Require precise heat control to maintain material properties -

Ultra-high strength steel ( uh( HSS)

Demand specific welding parameters to achieve proper fusion -

Boron steel

Necessitating higher current and shorter weld times -

Aluminum components

Require specialized settings for proper joint formation

Many automotive manufacturers directly specify exact spot weld parameters for collision repairs, make programmable spot welders essential for shops seek manufacturer certification.

Plasma cutters: precision cutting tools

While not weld equipment per se, plasma cutters often accompany weld setups in automotive shops. These tools use a high velocity jet of ionized gas to cut through metal with remarkable precision.

Automotive technicians rely on plasma cutters for:

-

Remove damage sections

Flawlessly cut out compromise metal before repairs -

Fabricate replacement panels

Create custom pieces when pre make parts aren’t available -

Custom modifications

Incisively shape metal for performance or aesthetic enhancements -

Rust repair

Remove corrode sections with minimal damage to surround metal

Professional automotive plasma cutters typically offer cut capacities between 1/4″ to 1/2 ” hickness, more than adequate for most vehicle metals. Many modern units feature pilot arc technology, which allow cut through paint or rusty surfaces without direct contact — ideal for automotive restoration work.

Plasma cutter accessories for automotive work

A complete plasma cutting station in an automotive shop includes:

-

Circle cut attachments

for creating precise circular cuts -

Edge guide

Ensure straight cuts along predetermine lines -

Multiple nozzle sizes

Different diameters for various cutting applications -

Air filtration systems

Remove moisture from compressed air to extend consumable life -

CNC interfaces

In advanced shops, allow computer control cutting for complex shapes

Many automotive shops directly opt for 3 in 1 or multiprocess machines that combine plasma cutting with mMIGand sometimes tTIGwelding capabilities, maximize utility while minimize shop space requirements.

Specialized welding equipment for aluminum

With the increase use of aluminum in modern vehicles, automotive shops have invested in specialized equipment design specifically for this challenging metal.

Aluminum focus welding equipment include:

-

Pulse MIG welders

Deliver control power pulses that reduce heat input -

Push-pull wire feed systems

Prevent the soft aluminum wire from bind in the feed line -

Dedicated spool guns

Keep the aluminum wire feed path short to prevent feeding issues -

Specialized cleaning tools

Remove the oxide layer that complicate aluminum welding

High-end automotive shops work oftentimes with aluminum oftentimes maintain separate welding stations solely for aluminum work. This prevents cross contamination issues that can compromise weld quality.

Safety equipment for automotive welding

Professional automotive shops maintain comprehensive safety equipment alongside their welding tools. These safety components are not optional but essential for proper operation.

Standard weld safety equipment include:

Source: Korean machinery.com

-

Auto darken helmets

With adjustable shade settings for different welding processes -

Flame resistant clothing

Protect against sparks and spatter -

Welding gloves

heat-resistant and offer adequate dexterity -

Fume extraction systems

Remove harmful welding gases and particulates -

Fire suppression equipment

Promptly accessible in case of emergencies -

Welding screens

Protect other shop personnel from arc flash exposure

Many automotive shops besides invest in specialized welding tables with integrate ventilation systems. These tables capture fumes from beneath while provide a stable, fire-resistant work surface.

Welding equipment maintenance in automotive shops

Professional automotive shops implement regular maintenance protocols for their welding equipment to ensure consistent performance and longevity.

Typical maintenance procedures include:

-

Daily inspection of cables and connections

Check for wear or damage -

Regular cleaning of wire feed mechanisms

Prevent feed issues that compromise weld quality -

Replacement of consumables

Maintain fresh contact tips, nozzles, and electrodes -

Gas system leak tests

Ensure proper shielding gas delivery and prevent waste -

Cool system maintenance

For water cool equipment like spot welders

Many shops maintain detailed maintenance logs for each piece of welding equipment, track consumable usage and schedule service intervals. This documentation oftentimes supports warranty claims and helps identify equipment near the end of its service life.

Emerging welding technologies in automotive repair

The automotive repair industry continues to evolve with new welding technologies design to address the challenges of modern vehicle construction.

Recent innovations include:

-

Cold metal transfer (cCMT)

A modify MIG process that reduce heat input, ideal for thin materials -

Resistance spot weld with adhesive

Combine traditional spot weld with structural adhesives for enhanced strength -

Laser welding systems

Become more accessible for high-end shops work on luxury vehicles -

Ultrasonic welding

For join dissimilar materials include certain plastics to metals -

Smart welding systems

Equipment that mechanically adjust parameters base on material detection

Forward think automotive shops progressively invest in training for these advanced technologies, recognize that stay current with welding innovations direct impact their ability to right repair newer vehicles.

Selecting welding equipment for an automotive shop

For shop owners and managers, choose the right welding equipment represent a significant business decision. The selection process typically considers several key factors:

-

Types of vehicles service

Different make require different welding capabilities -

Manufacturer certifications

Many require specific equipment to maintain certification -

Budget constraint

Balance initial cost against long term performance -

Space limitations

Consider the physical footprint of the equipment -

Staff expertise

Match equipment complexity to technician skill levels -

Future need

Anticipate evolve vehicle construction techniques

Many automotive shops develop relationships with welding equipment suppliers who can provide ongoing support, training, and maintenance. These partnerships oftentimes prove valuable when troubleshooting issues or upgrade equipment as need change.

Conclusion

The welding equipment find in modern automotive shops represent a sophisticated array of specialized tools, each design to address specific repair challenges. From versatile MIG welders to precision TIG systems, powerful spot welders, and complementary plasma cutters, these machines form the backbone of structural repair capabilities.

As vehicle construction continue to evolve — incorporate more aluminum, high strength steels, and mixed materials — weld equipment manufacturers respond with progressively advanced technologies. For automotive repair professionals, stay current with these developments ensure the ability to restore vehicles to their pre accident condition while maintain structural integrity.

Understand the capabilities and limitations of automotive welding equipment help shop owners make informed investment decisions while give customers confidence in the quality and safety of repairs perform. In the hands of skilled technicians, these specialized tools transform damage vehicles into roadworthy transportation, oft with no visible evidence of the repair process.